What is a Digital Twin?

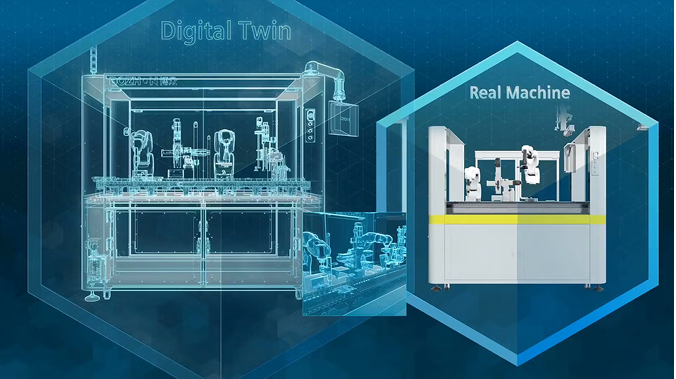

A Digital Twin is a virtual replica of a physical product, process, or system. It integrates real-world data, simulations, and analytics to mirror how assets perform, behave, and evolve over time. Unlike traditional models, a Digital Twin continuously updates with live data, enabling industries to analyze, predict, and optimize operations in real-time.

In simple terms: if you can see, test, and improve your product or factory in the digital world before touching the physical one—you save time, reduce costs, and accelerate innovation.