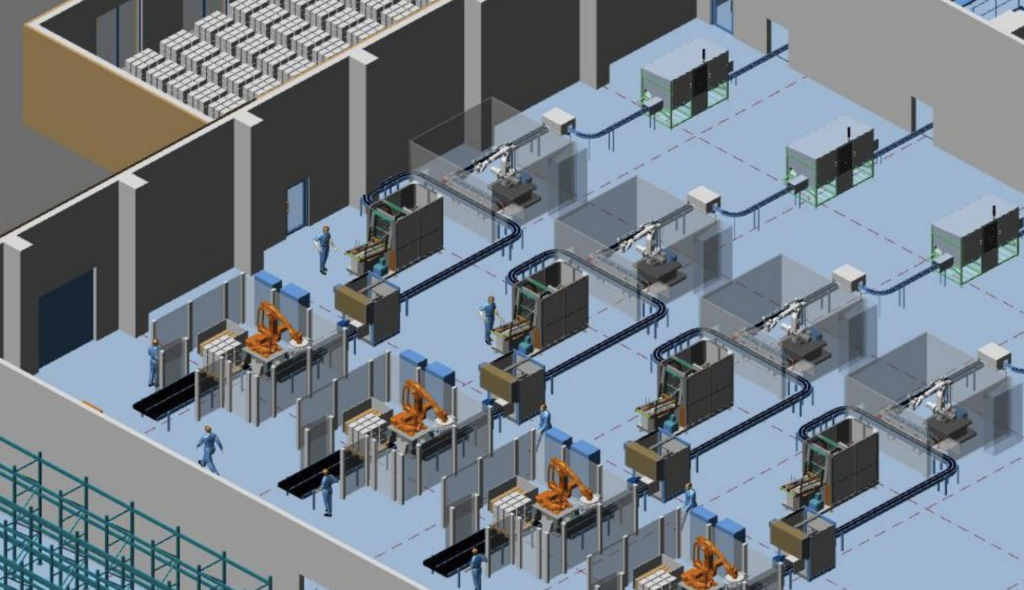

A 3D Factory is a digital depiction of an actual manufacturing plant created with advanced

modelling, simulation, and visualization techniques. This novel approach enables the

precise design, validation, and optimization of industrial layouts, equipment positioning,

and material flow prior to any physical construction or adjustments taking place.

The 3D Factory concept integrates cutting-edge technologies like Point Cloud Scanning,

CAD Modelling, Simulation, and AI-driven Automation to support Digital Thread and Digital

Twin strategies and improve operational efficiency and productivity.

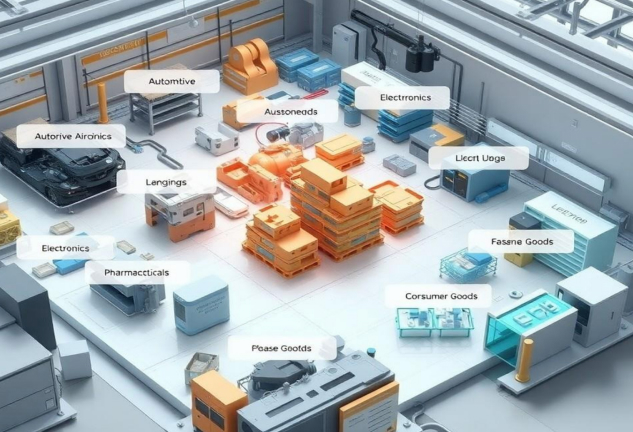

These virtual factories have numerous uses in companies with complex industrial setups.

Automotive: Enables manufacturing line modelling and optimization.

- Aerospace: Assist with assembly planning and process validation.

- Electronics: enabling micro-assembly and process modelling.

- Pharmaceuticals: designing cleanrooms and performing compliance testing.

- Consumer Goods: Improving packaging and warehousing layouts.

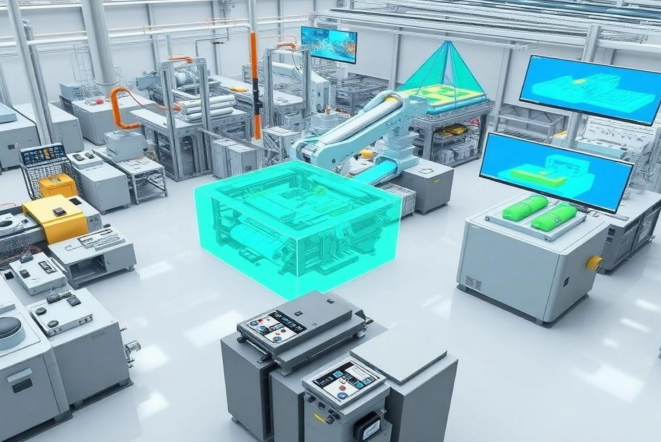

A 3D factory’s key use cases include designing and optimizing layouts for equipment

placement, assembly lines, and workflow.

- Virtual Commissioning: Validate automation systems prior to deployment.

- Process Simulation: Identify and resolve bottlenecks and inefficiencies in manufacturing processes.

- Ergonomic Analysis: Ensure that operator workstations are safe and comfortable.

- Digital Twin Creation: Create real-time data-driven models for predictive maintenance and performance tracking.

- Training and education: Effectively train operators and engineers using VR/AR environments.

- Scalable Production Planning: Change layouts and procedures quickly to meet changing production needs.

Implementing a 3D Factory has several benefits, including cost reduction through reduced

rework, downtime, and prototyping.

- Faster Deployment: Streamline the design and commissioning procedures to expedite implementation.

- Improved Accuracy: Test designs in a simulated environment to avoid mistakes.

- Flexibility: Easily adapt to new situations.