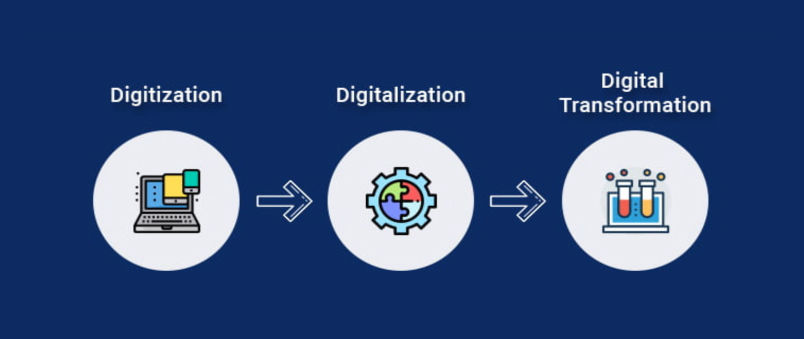

In an era marked by rapid technological advancements, manufacturing is experiencing a profound transformation. The integration of digitization, digitalization, and digital transformation is not only redefining traditional processes but also setting new benchmarks for efficiency, agility, and innovation.

1. Digitization in Manufacturing: Enabling Foundational Data Conversion

Definition: Digitization refers to the conversion of analog information into digital formats, serving as the foundation for advanced manufacturing systems.

Use Case: Modernizing legacy blueprints into CAD models to improve accessibility and adaptability.

Example: Transitions from 2D paper drawings to dynamic 3D CAD models, enabling precise simulations and iterative design modifications.

Benefits:

- Accelerated design iterations and updates.

- Enhanced data security and storage.

- Improved collaboration across geographically distributed teams.

2.Digitalization in Manufacturing: Streamlining Operations Through Connectivity

Definition: Digitalization involves the adoption of digital technologies to enhance workflows, automate processes, and improve decision-making capabilities.

Use Case: Deploying a Manufacturing Execution System (MES) for real-time production monitoring and control.

Example: Leveraging digital dashboards to track production performance, identify bottlenecks, and enforce quality standards.

Benefits:

- Increased operational transparency and traceability.

- Reduction in production downtime and resource waste.

- Enhanced responsiveness to market and production changes.

3.Digital Transformation in Manufacturing: Enabling Smart, Predictive, and Scalable Systems

Definition: Digital transformation represents the holistic integration of digital technologies across the enterprise to drive innovation, flexibility, and competitiveness.

Use Case: Implementing Digital Twin technology to simulate and optimize the end-to-end production lifecycle, including material procurement, assembly, and logistics.

Example: Integrate Digital Twin with IoT sensors and AI algorithms to enable predictive maintenance, reduce operational disruptions, and optimize resource utilization.

Benefits:

- Proactive identification and resolution of equipment failures.

- Accelerated time-to-market through virtual testing and validation.

- Significant cost savings and sustainability improvements.

Charting the Future of Manufacturing: A Digital Perspective

The convergence of digitization, digitalization, and digital transformation represents more than an evolution in manufacturing practices—it marks a revolution in industrial strategy. These technologies collectively enable manufacturers to:

Foster data-driven decision-making.

Create agile production systems adaptable to shifting demands. Integrate predictive analytics for sustained operational excellence. Implication:

This digital paradigm shift calls for a multidisciplinary approach, combining fields such as mechanical engineering, data science, cyber-physical systems, and artificial intelligence.

Future research should focus on:

- Developing robust frameworks for digital integration.

- Exploring hybrid modelling techniques for system optimization

- Assessing the socio-economic impact of smart manufacturing technologies.

Next Steps: Bridging Theory and Practice

Manufacturers and researchers must collaborate to bridge the gap between theoretical models and industrial practices. Simulative tools like Digital Twin, MES integration, and AI- driven analytics offer promising avenues to test hypotheses and refine methodologies. Embracing this academic-industrial synergy will unlock new possibilities for smart manufacturing ecosystems, ensuring sustained growth and innovation.