Drive Smarter Manufacturing Decisions

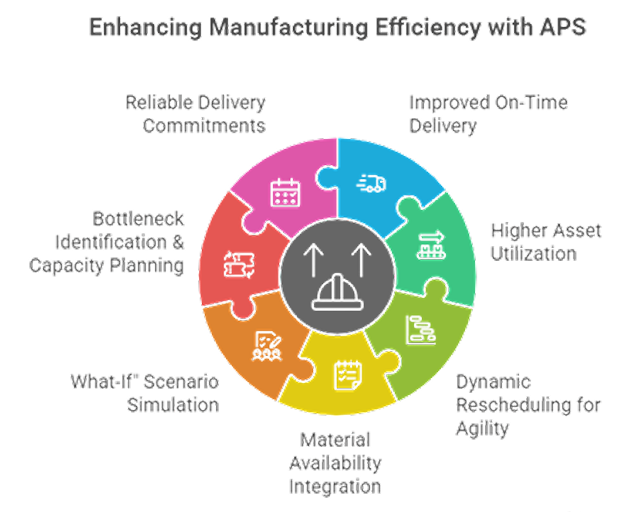

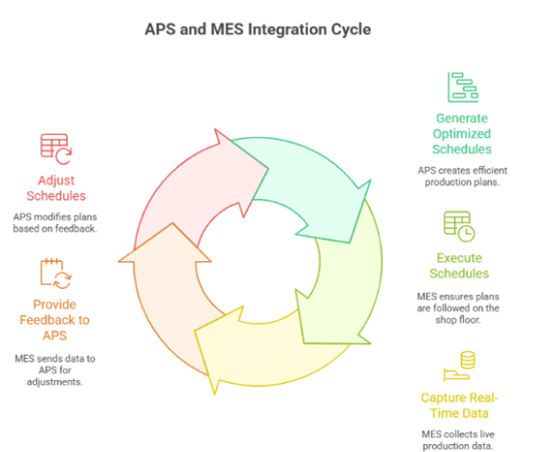

In today’s highly competitive and fast-paced manufacturing environment, delivering the right products on time while optimizing resources is key to success. Advanced Planning and Scheduling (APS) offers a strategic solution that empowers manufacturers to transform production planning from reactive guesswork into a data-driven, efficient process.