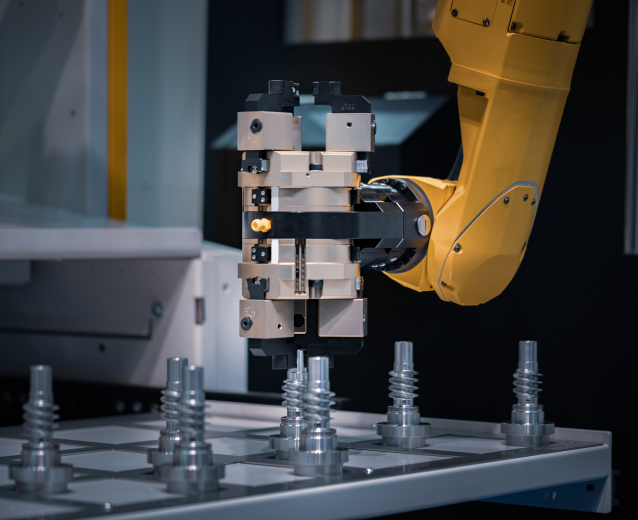

Robotics & Automation

Across all major industries, market pressures and structural costs require manufacturers to build more automation and increased flexibility into their production facilities. Individual plants must increase the number of products they can create while exceeding their current quality targets and optimizing their shop floor footprint. Manufacturers must rely more on robotics and automation systems to gain flexibility for more complex manufacturing operations and boost production efficiency.