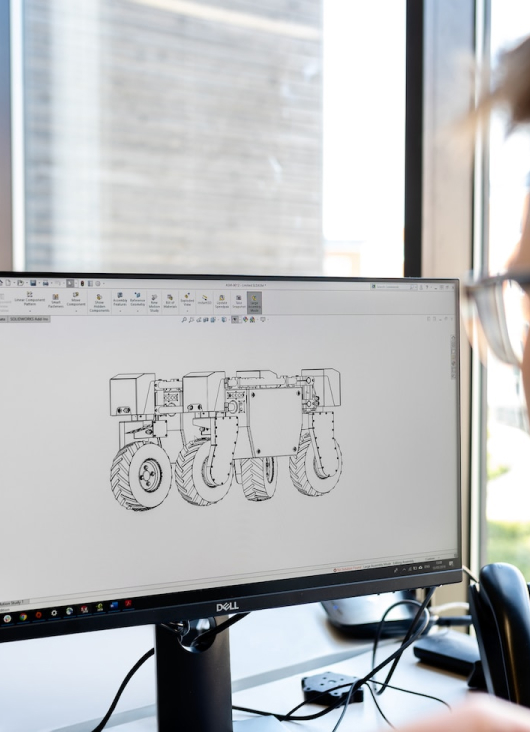

Indish Technologies is authorized to sell, support and train on NX CAD/CAM Products in India. As an authorized distributor we maintain these clients with our strong Technical support and continuous training on the updates on NX Software. We have a strong team of professionals who are experienced in Product Design and Complex Manufacturing Process including 3 to 5 Axis Machining.

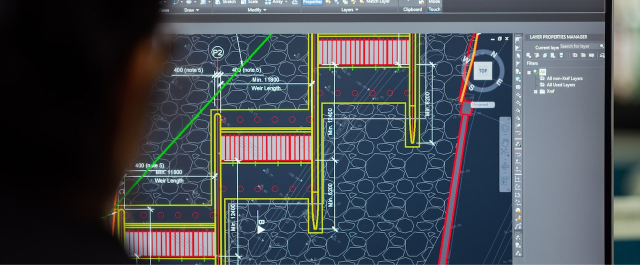

Increasingly the need for technological solutions that can be a complete solution as our offering of NX, to a process from the beginning to the completion stage is needed. The integration of various components and processes on a larger scale of things is needed to have an efficient control and understanding of the product. The integrity of the data from the concept design phase to the manufacturing has to be maintained and validated for the effectiveness of the data acquired. We provide that ability to our users and customers through the NX solution which helps them in realizing their goals and adding true value to their business with technological assistance. The user is able to encompass the whole process of product development to manufacturing through the integrated software solution that provides them with various tools in the process of design, simulation, test, and manufacturing solutions that plays a vital role in streamlining the entire process and delivering efficient results.

Supporting every aspect of product development, from concept design through engineering and manufacturing, NX gives you an integrated toolset that coordinates disciplines, preserves data integrity and design intent, and streamlines the entire process.