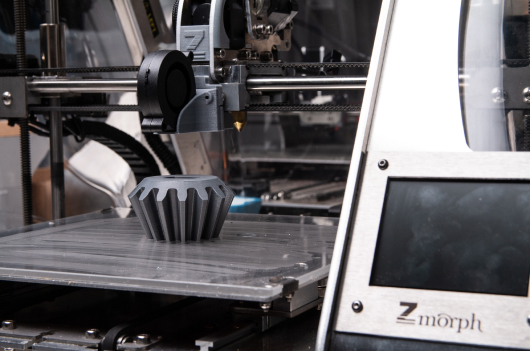

Selective Laser Melting (SLM) metal 3D printing is a cutting-edge technology that allows to produce high-quality, complex metal parts. This technology uses a high-power laser to melt and fuse metal powders layer by layer, creating a 3D object.

Selective Laser Melting (SLM) metal 3D printing is a cutting-edge technology that allows to produce high-quality, complex metal parts. This technology uses a high-power laser to melt and fuse metal powders layer by layer, creating a 3D object.

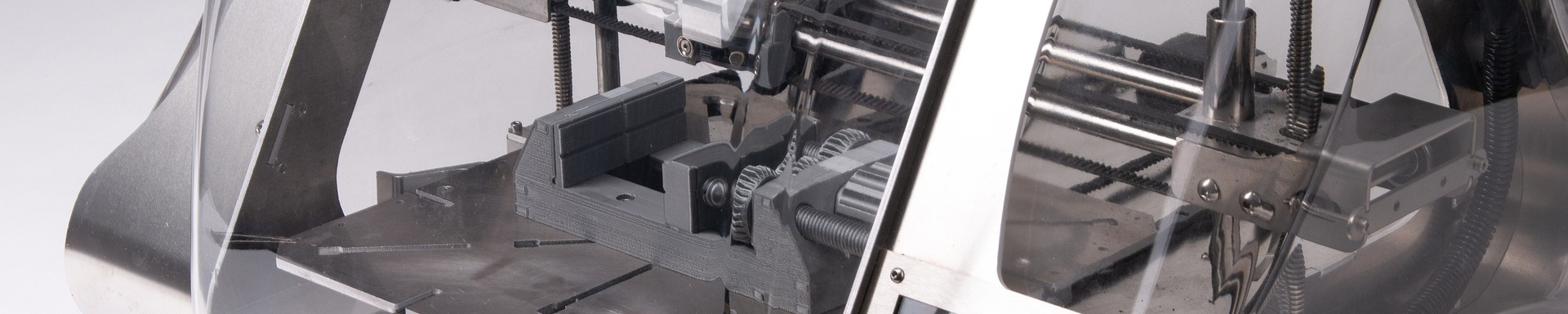

SLM metal 3D printing offers several advantages over traditional manufacturing methods such as casting, machining, and welding.One of the key benefits is its ability to produce highly complex and intricate parts with fine details, internal structures, and geometries that require more than traditional manufacturing methods.

SLM metal 3D printing is a green technology, as it generates less waste and reduces the need for post-processing, and it is also a cost-effective way to produce parts.Another advantage is the ability to create parts with optimized weight and strength using lattice structures and other light weighting strategies, making it ideal for aerospace, medical, and automotive industries.

SLM metal 3D printing is a powerful technology that offers a wide range of benefits for a variety of industries. Its ability to produce highly complex and intricate parts, use a wide range of materials, and its cost-effectiveness and eco-friendliness make it a versatile and valuable tool for manufacturing, prototyping, and low-volume production.